Materials Used in Selective Laser Sintering 3D Printing Explained

Have you always thought that 3D printed parts are flimsy and break just too easily? Yeah, they do, sometimes. But luckily, 3D printers today are capable of a whole lot more if you pick the right technology and material. You can create high-quality, long-lasting end-use parts for a wide range of applications. Not only that, you can do it quickly and cost-effectively on a compact 3D printer from your office, workshop, or manufacturing facility.

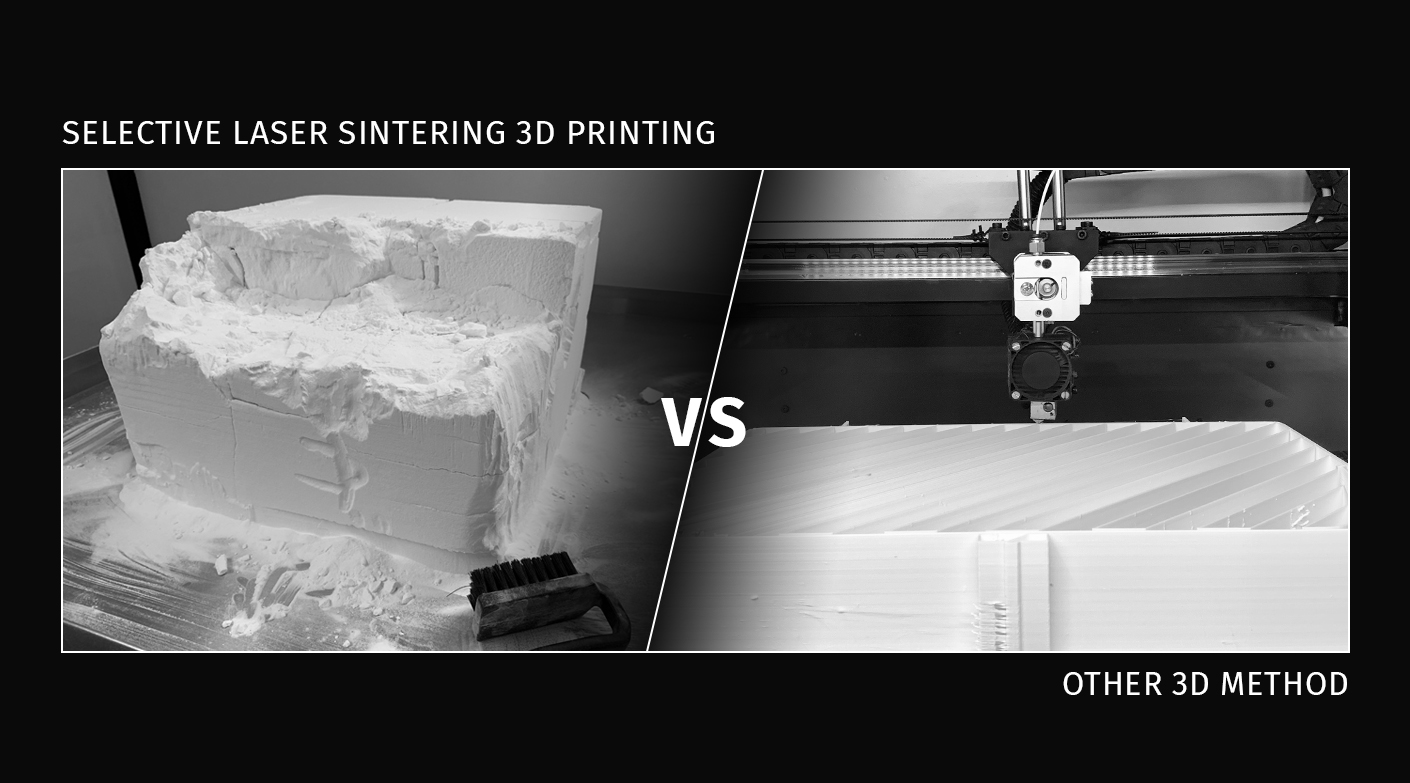

Selective Laser Sintering (SLS) emerges as one of the most popular 3D printing technologies that can create highly accurate and durable parts. But how does the SLS process work, and what materials are actually used in it?

In this blog, let’s showcase materials used by the most common 3D printing technology, Selective Laser Sintering.

What is Selective Laser Sintering 3D Printing?

Initially, Selective Laser Sintering 3D Printing was regarded as a means of rapid prototyping, yet it was soon revealed that the technology could be applied in a broad spectrum of other Industries, such as medicine, engineering, and production of consumer goods. SLS, or Selective Laser Sintering, is one of the most popular types of additive manufacturing these days, which provides more and more opportunities to businesses and customers.

How Does the SLS Process Work?

But how do such printers work? Selective laser sintering, as the name suggests, uses a high-powered laser to heat the printing material, which is always in a powder form, to make a solid object. The heat applied to the powder is sufficient to sinter rather than to melt it.

You require a CAD file or a 3D scan to initiate printing, requiring that you export them to a 3D printable file format, such as OBJ or STL, before the printing process begins. The build chamber, containing powder, is preheated in the printer at a temperature slightly below the sintering point, and printing starts.

The powder is dispersed in a thin layer on the print bed, and the laser heats certain areas so that the powder centers and forms the first solid layer of the future model.

The print bed then spins slightly and repeats the process until the job is completed.

Post-Processing of SLS Parts

After finishing your 3D model, you will be required to cool it and remove the residues of unglued powder at a cleaning station. Then it’s for you to decide whether to use it right away or add some post-processing like sandblasting or polishing.

Materials Used in Selective Laser Sintering

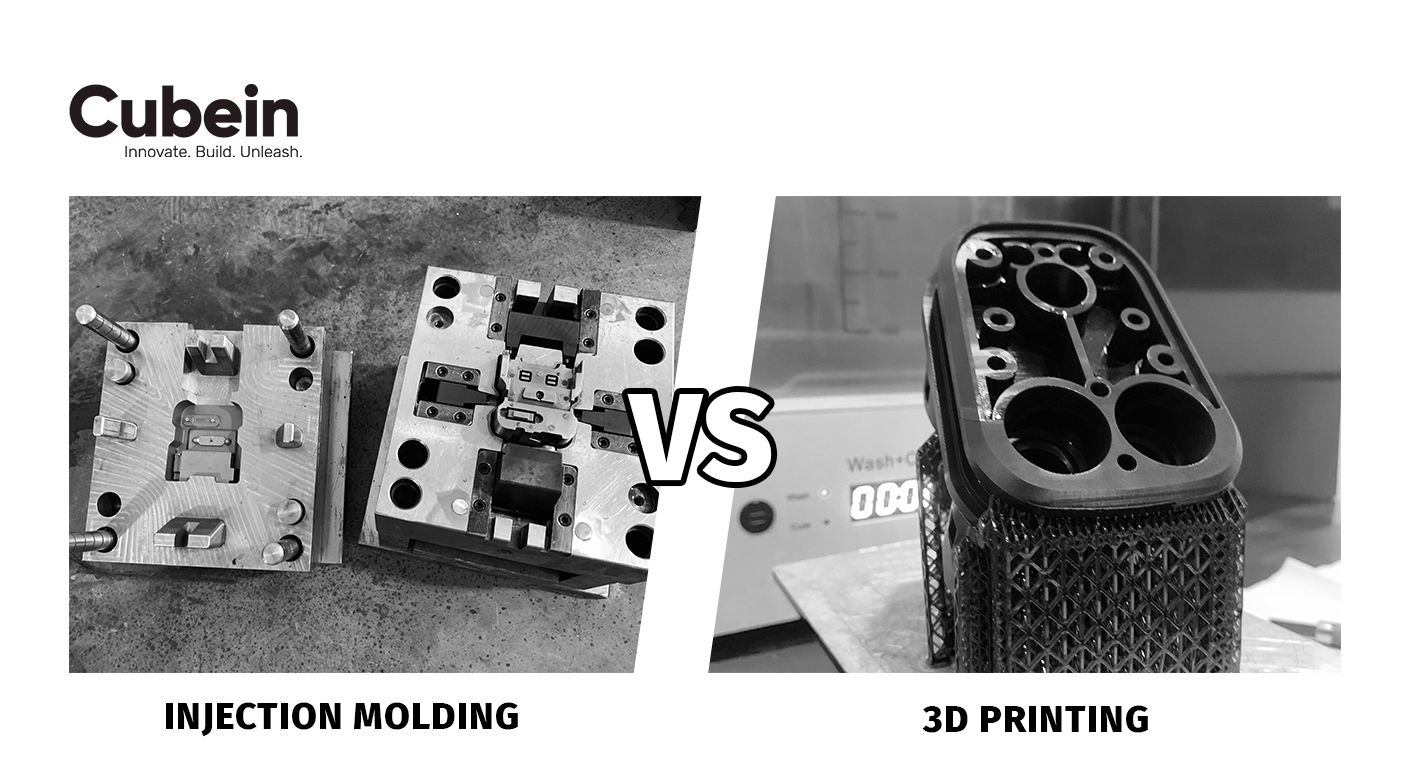

SLS 3D printers utilize a powerful laser to sinter tiny particles of thermoplastic powder. SLS 3D printers provide materials of good mechanical properties, like those of injection-molded parts.

Nylon (Polyamide)

Nylon SLS 3D printing material is the most used and popular engineering thermoplastic, lightweight, strong, and flexible, stable to impact, chemicals, heat, UV light, water, and dirt.

Nylon 12

Nylon 12 powder is the generally preferred SLS material, which is suitable for both functional prototyping and end-use manufacturing of complex assemblies and long-lasting parts, also with high environmental stability.

Nylon 11

Nylon 11 is a more functional substance that has the same properties as Nylon 12, with greater elasticity, elongation to break, and impact resistance, but is less stiff.

Reinforced Nylon

Other materials can also be reinforced to improve the performance of nylon, such as the addition of glass to reinforce rigidity or the use of carbon fiber to make it lightweight and powerful.

- The glass-filled nylon enhances rigidity.

- Carbon fibre-reinforced nylon is strong and lightweight, a design that is appropriate in the automobile and aerospace industries.

TPU (Thermoplastic Polyurethane)

Not only nylon, but also flexible TPU parts can be produced by SLS printers with the same level of design, freedom, and ease. TPU is a flexible material that stretches a lot without breaking and resists tearing; therefore, it is very useful in working prototypes and finished products.

Emerging Materials in SLS 3D Printing

Nylon and TPU are being market leaders, but research and innovation are leading to new materials for Selective Laser Sintering 3D Printing:

- Alumide (Nylon + Aluminum) to mimic metals in appearance and rigidity.

- Composites for custom applications.

- Biocompatible powders for implants as well as medical devices.

This set of materials expands the industry coverage of SLS 3D printing services.

The global Selective Laser Sintering market is expected to increase to USD 5.8 billion by the year 2032, with a strong CAGR of 12.88 percent. Such massive expansion reveals the necessity to select the correct materials, such as nylon, TPU, and composite materials, to extend the application of SLS in medicine and other fields.

Trusted 3D printing companies, like Cubein, understand that 3D printing in medical equipment is not only cutting-edge technology, but it is an actual breakthrough. SLS is redefining the bounds of healthcare with patient-specific, sterilizable, and high-performance components. Cubein believes in contributing to this revolution by providing quality design, material, and manufacturing services.

To see how SLS 3D printing in medical devices is revolutionizing patient care, click here.

The Importance of Material Choice in Selective Laser Sintering

The choices of materials in Selective Laser Sintering determine the mechanical power, solidity, stretch, and eco-friendliness of the end product. Proper selection of the material will ensure that the businesses can conveniently transition through the prototyping and the final-use production.

An example is that in Selective Laser Sintering, the final product is directly influenced by the materials you use:

- Mechanical Strength (rigid nylon vs. flexible TPU)

- Biocompatibility and Sterilization (necessary for medical applications)

- Durability and Functionality for end-use parts

- Potential for customization for patient-specific design

Conclusion

Due to the wide selection of materials available, SLS will be able to make detailed, strong, and complex models with almost all the properties required. The materials, using nylon, reinforced composites, TPU, or medical-grade powders, bring about new opportunities for industrial components to medical implants.

At Cubein, we specialize in SLS 3D Printing services to assist industries in introducing precision, durability, and customization to life, both in the form of medical devices and end-use products.

| Looking for a reliable partner to scale your production with precision and efficiency? |

FAQs

1. What are the common materials that we use in SLS 3D printing of medical devices?

A. Common nylon powders (PA12, PA11), glass-filled nylon, and biocompatible/resorbable powders are used due to their strength, elasticity, and sterilization ability.

2. Does the material of SLS matter to a final product?

A. Absolutely. The strength, flexibility, and longevity of the final part also depend on the selection of the material.

3. Can SLS components be sterilized to be used in surgery?

A. Yes. SLS components, especially biocompatible components, are sterilizable (i.e., can be subjected to sterilizing technologies like autoclaving).

4. Can SLS 3D Printing produce flexible parts?

A. Yes, shock-resistant, durable, and flexible parts may be made with such materials as TPU.