- SyBridge Technologies

Discover the Might of Injection Tooling & Production

Injection Tooling & Production refers to manufacturing the final product in large quantities, exactly as intended, without any further changes or design amendments.

These products are as originally conceived & ideated, high-quality, well-designed, and highly functional, with negligible chances of defects.

When to opt for Injection Tooling & Production?

Before going for a complete rollout of the final product with all the requisite functionalities, it is advisable to ask ourselves a few questions in order to determine whether Injection Tooling & Production would be the best option.

- Has the product attained the desired form as conceived?

- Is there a need for further design adjustments?

- Were the low-volume manufacturing results satisfactory?

- Is the prototype or development model working as intended?

- Is there a significant demand-supply gap in the market?

There are many other queries that decide the course of action one should take, if you are still in confusion, connect with out production engineers now

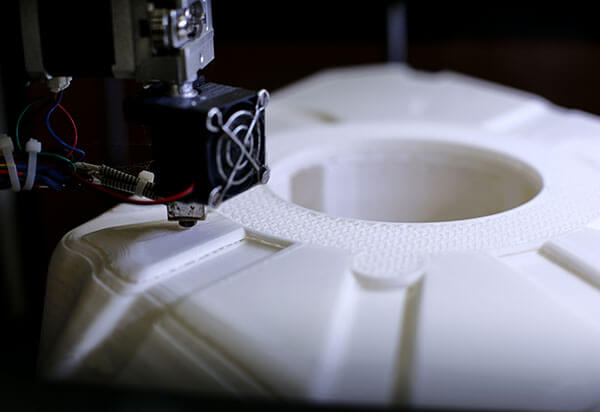

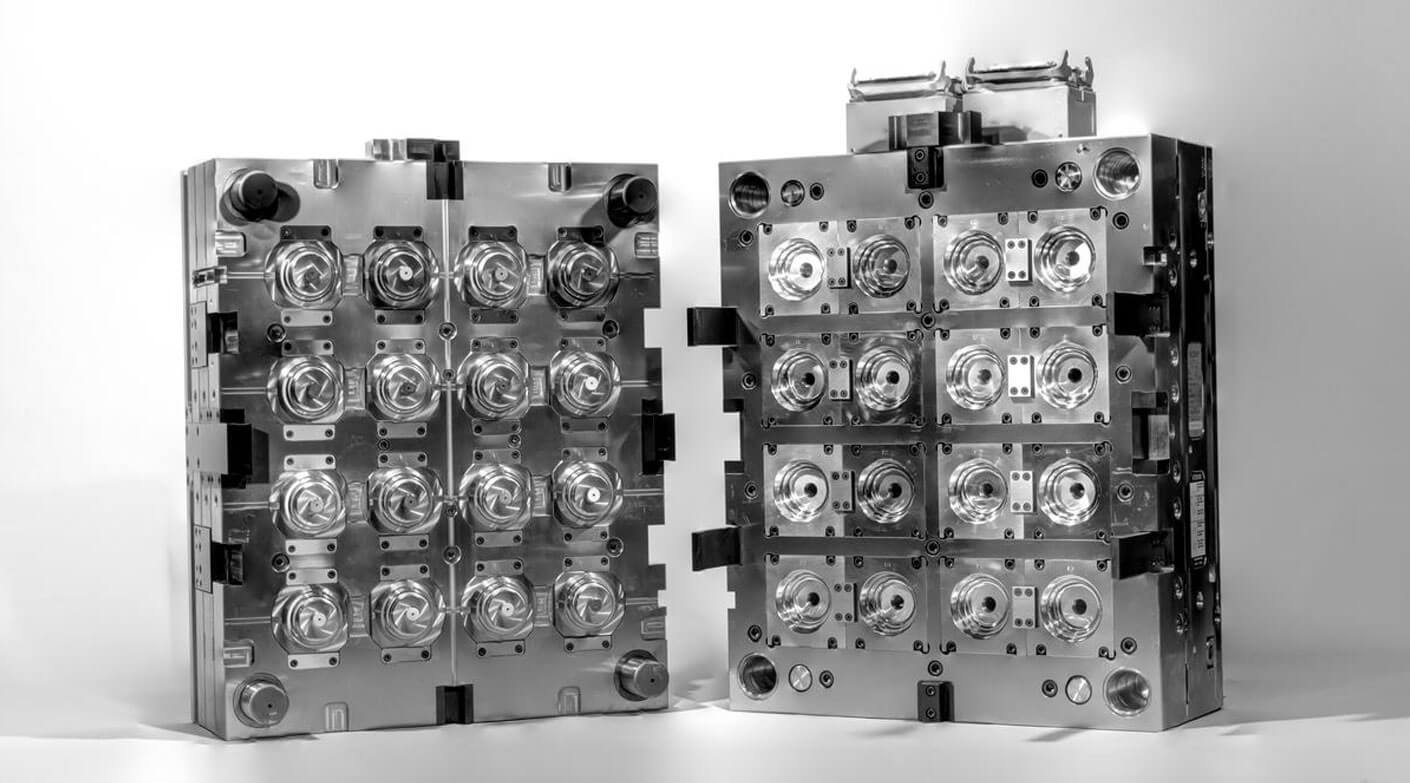

connect with our production engineers nowExploring Limitless Possibilities With Injection Tooling & Moulding

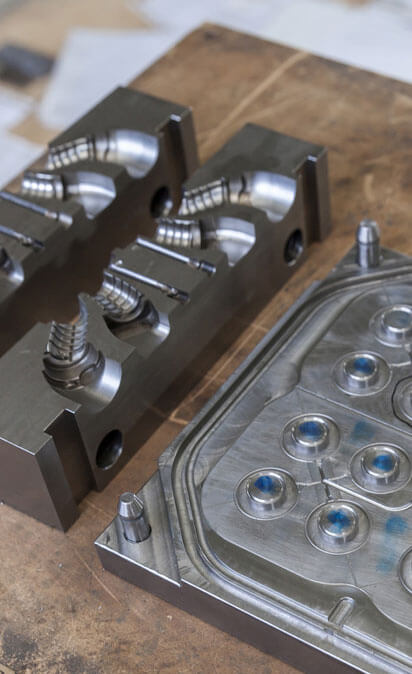

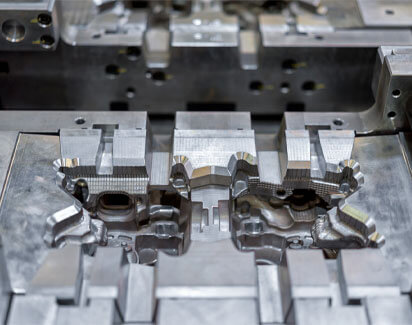

Injection Tooling & Moulding

Our top-notch injection molding and tooling service covers everything from material identification to product development. We can produce a wide variety of structures, including complex shapes, with high accuracy and quality. Using different resins and plastics, we inject the material into molds to create mass-produced products that can be customized.

Inquire NowBenefits of Injection Tooling & Moulding

- Ensures uniform and precise parts with every production run.

- Rapid production cycles reduce lead times and boost output.

- Economical for mass production with lower per-unit costs.

- Allows for intricate and challenging part designs.

- Works with a wide range of materials for diverse applications.