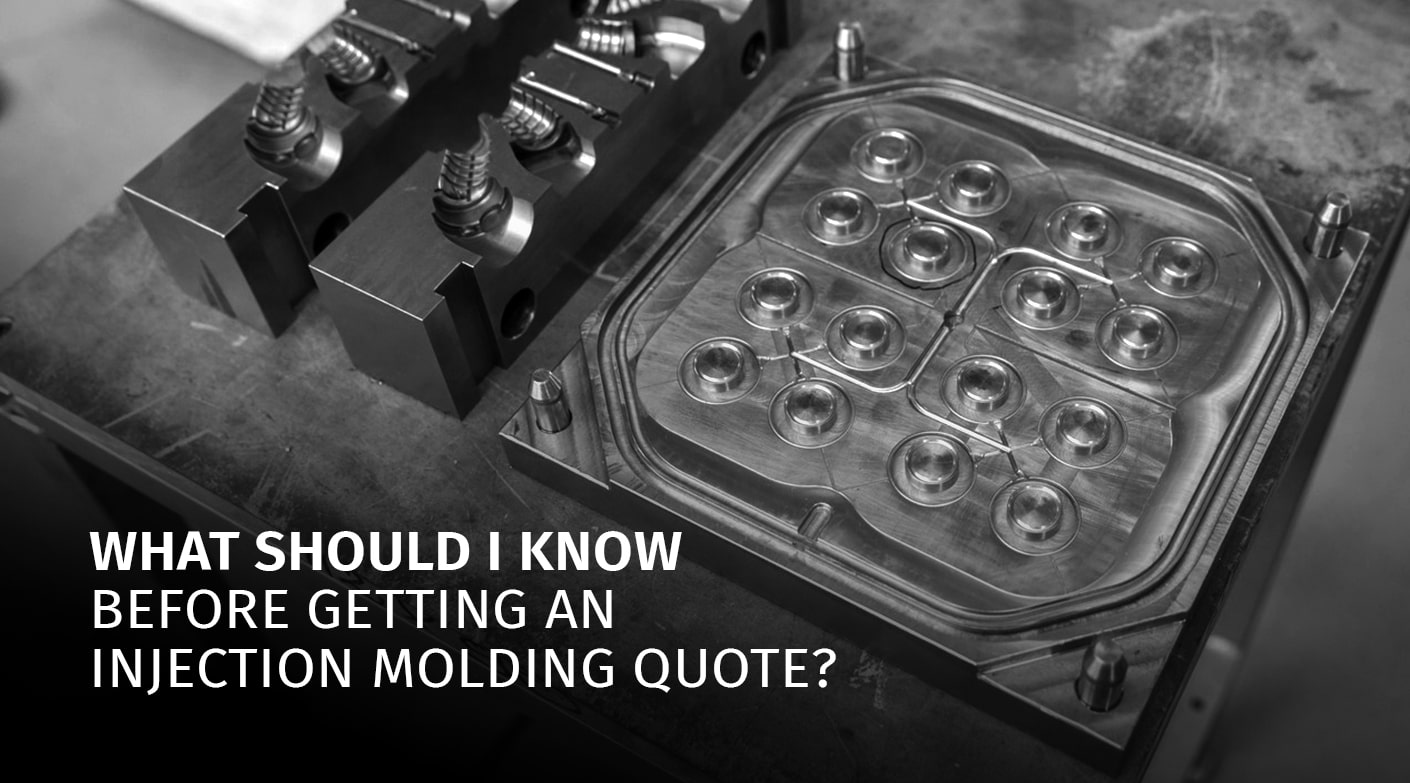

What Should I Know Before Getting An Injection Molding Quote?

When you want to transform your product idea into a workable reality, the first significant step is usually asking an injection molding company to provide you with a quote. However, many companies enter the quoting process without the clarity required to obtain a correct, realistic quote. An injection molding quote is influenced by much more than size or geometry; the maturity of the design, tooling expectations, materials, volumes, and long-term manufacturing goals all play a part.

To product developers, startups, and established brands, having an understanding of how a quote is created leads to quicker decision-making, reduced risk in production, and a smooth interaction with the plastic injection molding manufacturers.

Let’s cover everything you need to know before requesting a quote for injection molding.

What Drives Your Injection Molding Quote? 8 Key Factors

1. Start with a Fully Defined Design Package

The initial component that any injection molding company would consider is your product design. A complete design package provides clarity to the manufacturer, less back-and-forth, and discourages alterations that are expensive in the future.

Essential files to prepare:

- 3D CAD model (STEP/IGES recommended)

- 2D technical drawings including tolerances.

- Wall thickness details

- Notes on surface finish

An improved CAD model enables an engineer to evaluate the manufacturability, determine geometry that makes tooling difficult, and suggest how to improve it. Quality injection molding begins with quality design inputs. In their absence, manufacturers would have to guess, leading to prices that are either overpriced or unpredictable.

Why this matters: A mature design minimises tooling risks, enhances predictions of cycle time, and leads to a more precise quote, i.e., fewer surprises once production has begun.

2. Explain Your Production Volume and Purpose of Use

Volume is one of the largest cost enablers in injection molding. The number of units produced determines the kind of mold, raw material, the number of openings, and the production plan.

Ask yourself:

- Is the batch pre-production or prototyped?

- Am I required to have low-volume manufacturing to test the market?

- Is the product entering mass production on a long-term basis?

Low-volume runs usually depend on less expensive and faster-to-manufacture aluminium or modified steel tooling. Large-scale manufacturing requires robust, hardened steel molds lasting hundreds of thousands or millions of cycles.

Clarity in the volume plan aids plastic injection molding manufacturers in maximising tooling and offering cost-per-part on various levels of scale, allowing you to plan your product lifecycle.

3. Understand the Material that Suits Your Product Needs Well

The costs of parts, the complexity of the molds, functionality, and durability are greatly influenced by the choice of materials. The mechanical and thermal properties of the various plastic resins are distinct.

Ordinary injection molding materials are:

- ABS, which is highly suited to consumer goods, is quite hard and rigid.

- Chemical-resistant and flexible polypropylene (PP).

- Polycarbonate (PC) is colourless and shockproof.

- Nylon (PA) has high resistance to wear and strength.

- TPU is flexible and rubber-like.

Selecting the appropriate material will make sure that your design works as planned, in electronics enclosures, automotive components, medical enclosures, or mechanical assemblies.

Surface finish matters too: The tooling cost and the adjustment of molding are affected by textures, glossy finishes, matte patterns, and coating requirements.

Providing this information early generates a more accurate and reliable quote.

4. Learn the Complexity of Tooling and Cost

Your total quote depends on your tooling, which is, in most cases, the costly aspect of the injection molding process. The cost of tooling is based on geometry, surface quality, and tolerances, the number of cavities, and the choice of mold steel.

What affects tooling price:

- Number of mold cavities

- Mold steel type (aluminum vs steel)

- Complexity of design (undercuts, threads, deep ribs)

- Cooling system design

- Parting line placement

- Required mold life

Even minor design decisions can have a drastic effect on tooling effort. That is the reason behind the DFM (Design for Manufacturability) checks performed by advanced manufacturers prior to the start of tooling. This will match the expectations of engineering and cost, as well as efficient production at later stages.

5. Take Lead Time Expectations into Account Before Quoting

The injection molding schedules vary based on the project complexity, as well as the tools required, and production quantity.

Common timeline considerations involve:

- Tool design duration.

- Time of machining and polishing of molds.

- Testing cycles (T1 samples).

- Adjustments in the early experiments.

- Last approval and final production date.

Low-volume tooling tends to have a shorter turnaround time; however, high-volume hardened steel tooling requires more engineering time at the start, but it will be economical in the long run per part.

Knowledge of these time frames would enable you to schedule your manufacturing to meet the market demand or the time you need to launch your product to the market.

6. Industry Growth and Why the Right Manufacturing Partner Matters

The injection molding market is expanding due to increasing demand across various industries, including automotive, medical, and electronics.

. It has also been predicted that the worldwide market of plastic injection molding will hit USD 14.13 billion in 2034 (CAGR, 3.35%).

This expansion underscores the necessity of an industrial partner with inter-industry experience; an organisation that can lead in the selection of materials, ensure regulatory standards, and is able to maintain quality, both in prototype and full-scale production. Selecting the right partner gets your product scaled successfully in this fast-changing environment.

7. Assess the Advantages of Plastic Injection Molding

The advantages of plastic injection molding will make you realise why millions of products are produced through the process globally and, consequently, how your quote is formed.

Key advantages include:

- High repeatability: Ideal for large-scale manufacturing of the same parts.

- Minimum per part cost at volume: Works best with large production volumes.

- Flexibility in design: Supports complex geometries and functional integration.

- Surface Finishing: Good surface finish, minimised or removed after processing.

- Material versatility: Hundreds of plastics and additives to choose from.

- Effective cycle times: Rapid production in comparison with other processes.

These advantages imply that your initial investment in tooling could yield huge long-term savings compared to other manufacturing processes.

8. Make Your Expectations Clear

The better you can explain, the better and more precise your quote is.

Communicate early:

- Expected lifetime output

- Colour or finish specifications.

- Tolerance needs

- Regulatory standards

- Packaging and labelling specifications.

- Any special assembly needs

Manufacturers like to connect with well-prepared clients, as it helpsin cleaner processes, fewer revisions, and quicker production.

Conclusion

An injection molding quote encompasses more than just the price per part; it also considers design readiness, material selection, and the long-term manufacturing strategy.

With the right expectations when you reach the quoting stage, you will get not only the correct pricing but also effective production, as well as the seamless flow of the prototype and the finished product.

Cubein has the engineering expertise, flexibility, and industry knowledge necessary to convert concepts into market-ready products with confidence. At Cubein, your go-to plastic injection molding manufacturers, we can handle the entire development cycle, including design and prototyping, injection tooling, molding, low-volume manufacturing, and full contract manufacturing.

To get your injection molding quote, contact us now!

FAQs

1. What do I need to know to get a proper injection molding quote?

The trusted injection molding company Cubein offers a price for your project with a full CAD model, 2D drawings, materials selection, projected volumes, and details of surface finish quality.

2. Do I require large-scale manufacturing for injection molding?

No. Injection molding is also suitable when the volume to be processed is low, especially when low-volume tooling is used for prototypes, pilot production, or when it needs to be tested for the market.

3. What is the impact of material on the cost of injection molding?

The performance of parts, the design of the mold, the rule of shrinkage, as well as the cost, are all affected by the type of material. The correct resin will guarantee correct quotations and operation.

4. What is the average time of injection mold tooling?

Depending on the complexity of the design, size of the mold, the kind of steel to be used, and revisions required after the first trial run, tooling can require between 3 and 10 weeks.