Breaking Down the Costs: Injection Molding vs. CNC Machining

How do you strike a balance between quality and cost in the process of manufacturing? The businesses find these parameters quite important to fulfill their production demands. Analyzing expenses is crucial because every decision can impact the product’s launch and the company’s profit. Here is when injection molding and CNC machining help; they both make it possible to ensure precision, scalability, and save money.

Though Injection Molding wins at affordable production for many parts, CNC machining is easier for prototyping and manufacturing small batches. To choose the right process, you have to compare injection molding vs. CNC machining, look at their costs and the way these processes work. Product innovators depend on expert ODMs to achieve engineering expertise and gain an affordable output. Working with such manufacturers supports companies in shaping their decisions around tools, unit costs, and delivery times.

Let’s break down injection molding and CNC machining costs and choose the best process that meets your production needs.

Injection Molding vs. CNC Machining

An effective comparison between Injection Molding vs. CNC Machining is based on what makes them different, and understanding how these processes work.

| The global CNC machining market is forecasted to grow with a CAGR of 6.6% (from 2024 to 2030), and the injection molding market with a CAGR of 4.7%. The reason these processes are in high demand is their capability to produce a broad range of products with great accuracy and productivity. |

Injection Molding: A mold is used to create the product in injection molding, and the process begins with pouring the liquid plastic into the mold. As soon as the mold is made, it keeps producing uniform parts of the same quality and can handle tolerances of ± 0.020 inches.

The process is cheaper for producing large orders in the long run, but an initial investment has to be made in equipment up front.

CNC Machining: Parts are created with CNC machining by cutting down parts from blocks of metal or plastic, thanks to computers controlling the tools used.

Because molds aren’t needed, it allows rapid iterations and helps in creating fine components. It is especially useful for creating prototypes, producing small batches of goods, even in challenging shapes.

Key Differences

- Tooling Costs

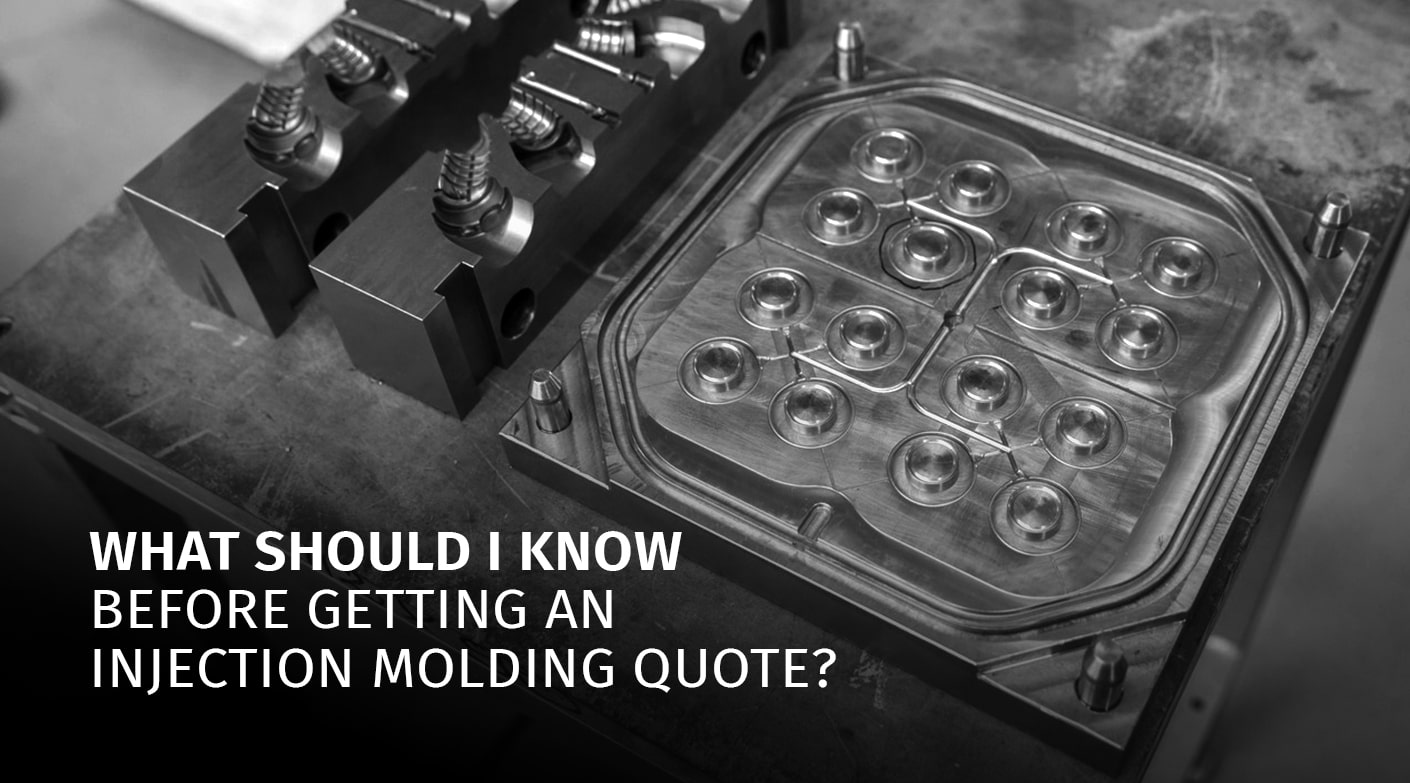

The main cost of Injection Molding is in the mold development part. Depending on the complexity, material, and purpose, tooling can be economical for around $2,000 or it can be much more at around $100,000.

With CNC Machining, the process doesn’t need any dedicated tooling. The cost includes the use of the machine, setup, and acquiring the raw material.

For any project that requires fewer than 100 pieces to be made, CNC machining is a better option. On the other hand, injection molding techniques enable users to create tools at low costs for runs of around 500 items.

- Per-Part Production Costs

The cost of making injection-molded parts decreases (from a few rupees or cents per part) when the mold is completed.

The process of CNC Machining is slow, so it costs more to produce a single part in large quantities.

In injection molding vs. CNC machining, the verdict is that injection molding is the best option for making a large number of parts (large-scale batch production) as it provides economies of scale.

- Lead Time

You have to wait up to 6 weeks for tooling in Injection Molding, but when ready, the mass production is done much faster.

In CNC Machining, rapid prototyping or making complex shapes can be done in only a few days.

The verdict is to use CNC machining when testing various designs and switch to injection molding when the product is ready for mass production.

- Design Flexibility

CNC Machining is known for creating products with intricate designs and intricate specifications, by using metals or strong plastics.

In Injection Molding, you have more flexibility in design, but the process is more limited by the flow of material, draft angles, and suitable tooling.

In short, CNC is used to make complex metal parts that need high precision, whereas injection molding deals with manufacturing plastic cases in bulk.

- Material Utilization and Waste

Injection Molding is good for the environment because it uses most of the thermoplastics and minimizes waste.

CNC Machining leads to a lot of waste because material is removed in a subtractive way.

The conclusion is that injection molding is a more responsible process when you use eco-friendly resins.

When to Use? A Cost-Based Decision Guide

| Application | CNC Machining | Injection Molding |

| Prototypes | Quick and Cost-effective | Higher Upfront Tooling Cost |

| Low-Volume Runs (10-100 items) | Full flexibility and no tooling needed | Is flexible with the guide to low-volume injection molding solutions |

| High-Volume Runs (1000+ items) | Tools for producing items are costly | Economical after tooling |

| Metal Parts | Metal Parts are preferred more | Prefers Plastic Materials more |

| Plastic Parts | Sometimes used for prototyping | Ideal choice for production |

Is 3D Printing A Competitive Alternative?

When concept validation or custom-shaped products create part of your product lifecycle, use 3D printing services in India as a support method. Additive manufacturing does not work for high-volume production, though it gives several specific benefits.

- Rapid prototyping

- Tools are not required to develop and test a design.

- Components made to suit medical or aerospace applications

For businesses looking to speed up their development process and be more innovative, Cubein provides complete 3D printing services.

Final Thoughts: Cost, Scalability, or Speed – What to Choose?

Both Injection Molding vs. CNC machining have their strengths and purpose, so the decision is not the same for every business. CNC machining is important for rapid iterations and prototypes, whereas injection molding helps with mass production that is both affordable and effective.

At Cubein, we are your ultimate ODM; we’re here to give you confidence while you navigate your decision. If you are seeking 3D printing services in India, a guide on low-volume injection molding, or partnering in global production, your search ends with Cubein. We bring precision, performance, and reliability to the production process, from start to finish.

| Looking for ways to improve your product manufacturing process?

Get a free consultation for your manufacturing strategy and cost management. |

FAQs

- Who provides injection tooling and production services in Ahmedabad?

We work with clients in Ahmedabad and other places, assisting them with swift tooling, prototyping services, and flexible molding solutions. Production is smooth and economical due to the network of manufacturing we have at home and internationally.

- What is Injection Molding Tooling?

The shape of the mold determines how plastics are created into final parts in injection molding. Most of the time, products are built out of hard steel or aluminum to withstand exposure to heat and frequent use.

- Can low-volume injection molding be considered a cheaper alternative to CNC machining?

When there are 100 to 10,000 units to be produced, low-volume injection molding is the most affordable option. It links prototyping with the main production by providing improved unit profits.