In the realm of manufacturing, efficiency, precision, and cost-effectiveness are paramount. Among the myriad of techniques available, vacuum casting stands out as a versatile and reliable method for producing high-quality prototypes and small production runs. In this blog, we delve into the intricacies of vacuum casting, exploring its process, applications, benefits, and the availability of vacuum casting services, particularly in India.

Understanding Vacuum Casting:

At its core, vacuum casting is a manufacturing process used to create highly detailed and dimensionally accurate prototypes and small-scale production parts. Also known as polyurethane casting or silicone molding, vacuum casting involves pouring liquid polyurethane resin into a silicone mold under vacuum pressure. This method allows for the replication of intricate details and textures, making it an ideal choice for producing prototypes that closely resemble the final product.

The Vacuum Casting Process:

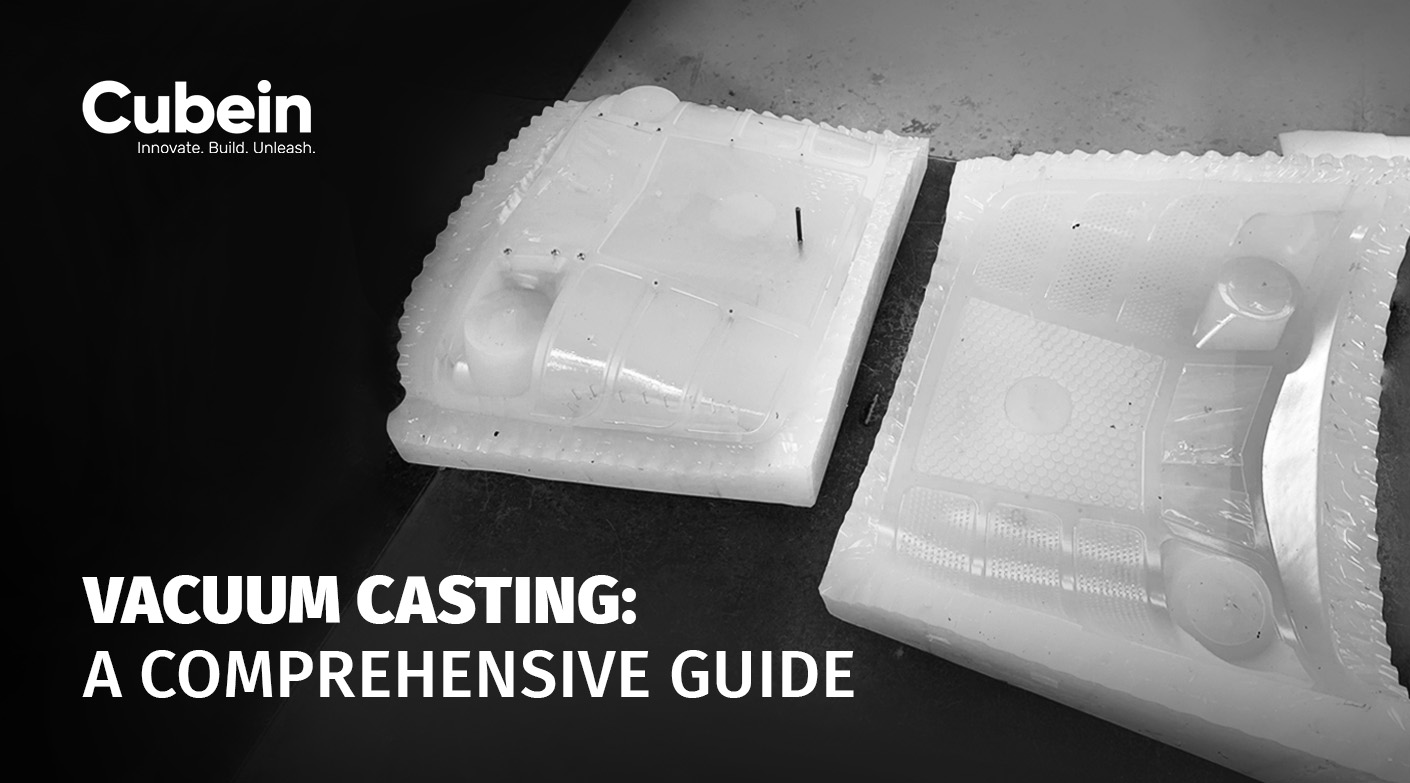

The vacuum casting process begins with the creation of a master pattern, typically made from a 3D-printed or CNC-machined model. This master pattern serves as the basis for creating the silicone mold. Next, a two-part silicone rubber material is poured over the master pattern, covering it completely. Once the silicone cures, the mold is cut open, and the master pattern is removed, leaving behind a negative impression of the original model.

With the mold prepared, the vacuum casting process can commence. Liquid polyurethane resin is carefully poured into the mold cavity. The entire mold assembly is then placed inside a vacuum chamber, where the air is removed to create a vacuum environment. This vacuum pressure helps to remove any air bubbles trapped within the resin, ensuring a smooth and uniform final product.

After curing, the resin solidifies, taking the shape of the mold. The mold is then opened, and the newly cast part is removed. Depending on the complexity of the part and the desired finish, additional post-processing steps such as trimming, sanding, and painting may be required.

Benefits of Vacuum Casting:

Vacuum casting offers numerous advantages that make it a preferred choice for prototyping and small-scale production. One of the primary benefits is its ability to replicate intricate details and textures with remarkable accuracy. This makes vacuum casting ideal for creating prototypes that closely resemble the final product, allowing for thorough testing and validation.

Additionally, vacuum casting enables the production of parts with a wide range of mechanical properties. By choosing the appropriate polyurethane resin formulation, manufacturers can tailor the material properties to meet specific requirements such as flexibility, durability, and heat resistance.

Furthermore, vacuum casting is a cost-effective solution for producing low to medium volumes of parts. Compared to traditional manufacturing methods such as injection molding, vacuum casting requires minimal setup time and tooling costs, making it an attractive option for small businesses and startups with limited budgets.

Vacuum Casting Services:

In today’s globalized marketplace, access to reliable vacuum casting services is essential for businesses seeking to bring their designs to life. Fortunately, a growing number of companies offer vacuum casting services, catering to a diverse range of industries and applications.

For those seeking vacuum casting services in India, there are several reputable providers like Cubein Advanced ODM, offering high-quality solutions. These companies leverage advanced technologies and state-of-the-art facilities to deliver precision-engineered parts with quick turnaround times. Whether you’re a product designer, engineer, or entrepreneur, partnering with a trusted vacuum casting service provider can streamline your prototyping and production processes, allowing you to bring your ideas to market faster.

In conclusion, vacuum casting is a versatile and reliable manufacturing process that offers numerous benefits for producing high-quality prototypes and small-scale production parts. From its ability to replicate intricate details to its cost-effectiveness and versatility, vacuum casting has established itself as a go-to solution for businesses seeking efficient and accurate manufacturing solutions.

With the availability of vacuum casting services, particularly in India, businesses can access the expertise and resources needed to turn their ideas into reality. Whether you’re a startup looking to validate a new product concept or an established company seeking to optimize your production processes, vacuum casting offers a cost-effective and efficient solution for bringing your designs to life.

So, the next time when you require precision-engineered parts, consider harnessing the power of vacuum casting from Cubein to unlock new possibilities and propel your business forward.