What would you think if your prototype acted like the final product, without compromises? The question lies at the core of the current product development. Indeed, engineers, designers, and innovators are not satisfied with models that merely look right. They require prototypes that can work, withstand stress, and validate use cases. Here, Selective Laser Sintering (SLS) 3D printing comes in as a game changer in functional prototyping.

Compared to traditional prototyping technologies that are either limited in design or use tooling, SLS 3D printing offers fast and high-performance iteration of designs through materials that closely mimic end-use plastics. The outcome is a prototype that does not merely reflect an idea, but puts it to the test in real conditions.

Let’s discuss the benefits, but first, understand SLS 3D Printing.

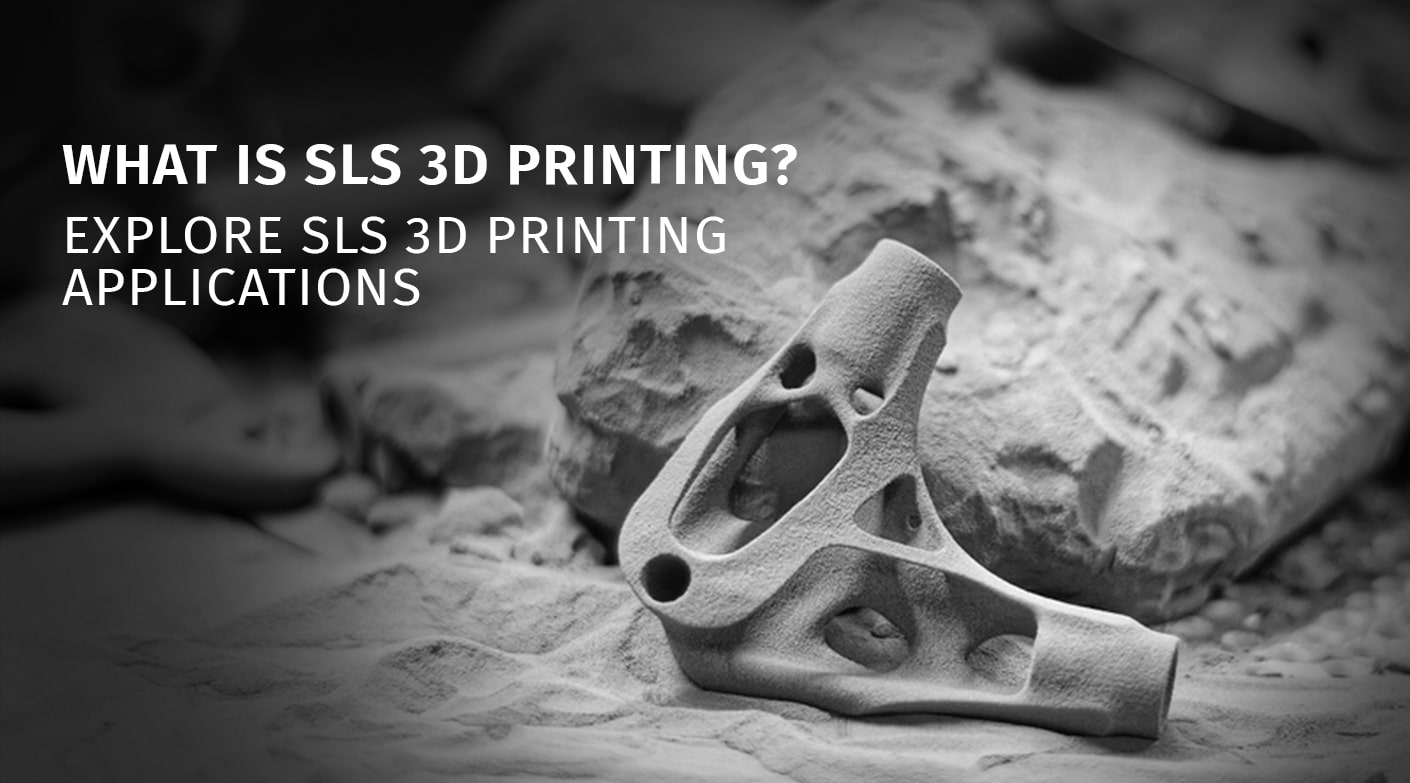

Understanding SLS 3D Printing

Selective Laser Sintering is an additive technique that employs a powerful laser to melt powdered materials in layers, mostly nylon, into solid components. The unsintered powder provides a natural support structure around the area, so there is no requirement for support.

This inherent distinction provides SLS an advantageous edge over technologies such as stereolithography 3D printing, which uses liquid resin and a support scaffold. As a matter of fact, the world Selective Laser Sintering market is projected to hit around USD 31.05 billion in 2034, with the double-digit growth projected to continue as industries embrace the use of Selective Laser Sintering as a quick and functional method of prototyping.

No doubt, Stereolithography is also a good option when it comes to surface finish and fineness, but SLS is designed to be strong, durable, and able to perform under high mechanical loads, so it is better suited to prototypes that are demanding.

| To know more about SLS 3D Printing, including what materials are used in this process, click here. |

The Importance of Performance Beyond Appearance in Functional Prototypes

Functional prototypes play a greater role than physical appearance and aesthetic validation. They are used to:

- Load-bearing capacity and test mechanical performance

- Assess snap-fits, hinges, and mobile assemblies

- Check ergonomics and real-world handling

- Conduct pre-certification and compliance testing

Conventional prototyping techniques usually fail in these respects. Injection molding is expensive in terms of tooling, and CNC machining restricts geometry, whereas not all resin-based prints are mechanically resilient. SLS bridges this gap, producing prototype-speed properties of production grade.

Furthermore, if we take the functional overview of SLS vs. Stereolithography 3D Printing, the two technologies both have significant applications in additive manufacturing, although their strengths differ:

- SLS 3D Printing: Ideal for mechanically strong, functional, and load-bearing prototypes.

- Stereolithography 3D Printing: Excellent in visual models, fine details, and smoothness.

In cases of functional prototyping where performance testing is important, SLS is very popular.

Key Benefits of SLS 3D Printing for Functional Prototyping

1. Outstanding Mechanical Strength and Durability

Mechanical integrity of the parts manufactured is one of the greatest advantages of SLS 3D Printing. SLS printed components have:

- Great tensile and impact strength

- Good resistance to fatigue

- Equal strength around every direction (near-isotropic properties)

This makes SLS printing appropriate in stress testing, functional assemblies, and in real-world simulations where failure is not an option.

2. Freedom of Design with No Support Structure

Designers have the freedom never before because SLS does not demand assistance. Complex internal channels, lattices, undercuts, and complex interlocking parts can be printed as one.

To prototype product functionalities, it involves:

- Fewer assembly steps

- Less chance of misalignment

- Exact testing of complicated geometries

This is hard to accomplish using stereolithography 3D printing or subtractive manufacturing techniques.

3. Realistic Testing of Production-Grade Materials

SLS usually works with powders made of nylon, including PA12 and PA11, which are characterized by:

- Chemical resistance

- Thermal stability

- Wear resistance

These material characteristics are quite similar to injection-molded plastics, and prototypes can act like finished products. This realism is priceless in the testing of functions, particularly in the automotive industry, medical equipment, industrial machines, and consumer goods.

4. Quick Innovations and Decreased Time to Markets

Speed matters in innovation. Using professional SLS 3D Printing services, one can go through the design iterations in days, not in weeks.

This quick turnaround will allow:

- Faster design validation

- Early identification of mistakes in the design

- Agile development cycles of the product

The result is that teams are able to refine designs with a sense of certainty by reducing the time it takes to obtain feedback.

5. No Tooling Costs, not even for Complex Parts

Conventional production methods tend to use costly molds or fittings. SLS is also cost-effective in eliminating tooling and is therefore useful in cases where:

- Low-volume production

- Multiple design variations

- Functional prototypes are customized

This cost-benefit is particularly useful where start-ups and R&D groups have to operate within strict budgets.

6. Efficiency in Batch Production

The SLS printers are able to print a series of parts at a time inside the same build chamber. As parts do not require personal supports, they can be tightly packed, hence building efficiency.

In the case of companies that deal with an established SLS 3D Printing firm, this translates to:

- Lower per-part cost

- Batches of similar quality

- Scalable redesignless prototyping

7. Surface Finish: A Balance between Function and Beauty

Although SLS components possess a rather grainy surface when compared to the stereolithography 3D printing, they are the perfect balance between form and functionality.

Moreover, it can be followed by post-processing methods (bead blasting, dyeing, coating) to improve the quality of the surface to present or test it on the user.

Industries Benefiting Most from SLS Functional Prototypes

The functional prototyping using SLS is commonly used in industries, such as:

- Automotive (ducts, housings, clips)

- Medical (orthopedic elements, enclosures)

- Electronics consumed (snap-fit casings, brackets)

- Industrial equipment (gears, covers, tooling aids)

In each of the scenarios, the capability to test real-world functionality prior to production is highly effective in mitigating risk and development cost.

Conclusion

Functional prototyping requires precision, and this is where the benefits of SLS 3D Printing shine through. Design freedom as well as material performance, along with faster iteration, are just some of the benefits of SLS. SLS 3D printing gives the innovator the freedom to test, in real-life conditions, before transitioning to production.

Advanced SLS 3D printing services at Cubein, your ultimate SLS 3D printing company, are integrated with engineering knowledge. At Cubein, we assist firms to turn their ideas into efficient and effective solutions, with confidence and speed.

FAQs

1. Why is SLS 3D printing perfect for functional prototyping?

SLS supports nylon materials through the manufacturing of strong and durable parts that enable the prototypes to endure mechanical and environmental testing.

2. What is the difference between stereolithography 3D printing, and SLS?

SLS is stronger and more functional, whereas stereolithography 3D printing is more competent in terms of surface finish and fine detailing.

3. Can small production runs be done on SLS 3D printing services?

Yes, SLS is very economically efficient when it comes to low to medium-volume batches, and no tooling expenses are required.

4. Are SLS prototypes end-useable?

Yes, in most situations, particularly with industrial components, housings, and custom parts where durability is necessary.