Two laser-powered technologies. One critical choice. You may have encountered the SLS vs. SLA controversy if you have been researching additive manufacturing. Both of the technologies are popular and precise, but their functioning is quite different. The decision between them is not about which is better, but rather which is more compatible with your product performance and scalability needs.

From the early prototype development stages to components ready for manufacturing, knowledge of SLS and SLA 3D printing can save time, reduce costs, and improve overall processes with significantly different results.

Let’s understand the functionality of the two technologies and their place in the modern manufacturing processes.

Understanding Laser-Based 3D Printing Technologies

As the 3D printing market is all set to exceed 134.58 billion by 2034, it is quite important to understand its technologies thoroughly. Although both technologies deal with lasers, the similarity does not go much further. There is a basic difference in the material form, printing process, and final part behaviour.

What is SLS 3D Printing?

Selected Laser Sintering (SLS) is a 3D printing method used for buildingpolymer materials with a high-energy laser. To facilitate the production of complex geometries and internal structures, the surrounding powder is likely to retain the part in place during printing, and supports are generally not required.

The major features of SLS 3D Printing:

- Powder materials made of polymer (typically nylon)

- No support structures needed

- Good mechanical strength and durability

- Best suited to complicated, practical, and finished components

SLS is commonly used in various industries where performance is critical, including automotive, aerospace, medical, industrial, and consumer products.

What is SLA 3D Printing?

The SLA 3D Printing (Stereolithography) system works on a concept of hardening a liquid photopolymer resin using a focused laser. The layers are solidified with the highest precision, producing parts with fine surface with smooth surfaces and fine details.

The key features of SLA 3D Printing:

- Liquid resin-based process

- Outstanding resolution and surface finish

- Needs support structures

- Post-processing involves washing and UV curing

SLA is particularly beneficial for visual prototypes and medical components, such as dental applications, and in validating designs where appearance and dimensional accuracy are critical.

SLS vs. SLA 3D Printing: Differences in the Core Processes

| Aspect | SLS 3D Printing | SLA 3D Printing |

| Material Type | Powder | Liquid Resin |

| Support Structures | Not Required | Required |

| Surface Finish | Textured (Slightly) | Very Smooth |

| Strength | High | Moderate |

| Post-Processing | Minimal | Extensive |

This comparison explains that the selection of the correct technology depends on the purpose of the part, and not only the appearance.

4 Key SLS vs. SLA Differences

#1 Material Options and Their Impact on Performance

SLS Materials: Built for Functionality

The materials mainly used in SLS are nylon-based powders, like PA12, PA11, and glass-filled composites. These materials offer:

- High impact resistance

- Heat and chemical stability

- Long-term durability

Since SLS components are isotropic (strength in all directions), they are useful in the axis of mechanical load- they can be perfect to use in functional testing and production.

SLA Materials: Designed for Precision

Standard, engineering, flexible, and castable resins are used as SLA materials. Despite their visual appeal, most resins are less strong than SLS polymers.

The SLA materials are best applicable to:

- Concept models

- Fit-and-form testing

- Highly detailed components

They are not so ideal for load-bearing or long-term mechanical uses.

#2 Surface Finish vs. Structural Strength

Among the most significant distinctions between SLS and SLA 3D printing lies in what the final part prioritises.

SLA: Exceptional Detail

SLA manufactures components with near injection-mould-quality surfaces that often require only minimal finishing. This is perfect for presentation models and aesthetic prototypes.

SLS: Industrial Grade Performance

SLS components can be slightly textured, yet they are better than SLA in the following sense:

- Strength

- Fatigue resistance

- Functional reliability

In a practical application, the emphasis should be on the design’s strength rather than its appearance.

#3 Speed, Scalability, and Production Efficiency

SLS for Batch Production

Since SLS does not require support structures, it allows nesting several parts and printing them in one build. This significantly enhances throughput and lowers part-level cost.

SLA for Small Runs

SLA is cost-effective when used with small batches and single-off prototypes, but less cost-effective at higher volumes because of the requirement of support removal as well as post-processing.

#4 Cost Considerations

Although the entry cost of SLA printers is usually less than that of alternative printers, the overall project cost is not entirely determined by equipment costs.

SLS Cost Factors

- Higher initial setup

- Lower post-processing labor

- Reusable powder

SLA Cost Factors

- Lower machine cost

- Higher material waste

- Further processes for curing and finishing

In applications where business requires repeat production or verifies a functional design, SLS can offer superior long-term value.

Selective Laser Sintering 3D Printing vs. Other 3D Methods

Compared to FDM, PolyJet, or simple resin printing, Selective Laser Sintering 3D Printing is described by its strength, design freedom, and scalability.

How SLS works better than many other 3D techniques:

- Manufactures isotropic components that are equally strong in every direction

- Allows functional testing and usability

- Removes support-related design constraints

- Facilitates production in batches with efficient nesting

This makes SLS particularly useful when transitioning to short-run or bridge production beyond prototyping.

Benefits of SLS 3D Printing

Among all additive manufacturing technologies, the advantages of SLS 3D printing are most evident in challenging, performance-based settings.

1. Strength and Durability

The SLS components withstand impact, heat, and fatigue and can be used in functional assemblies and end-use parts.

2. Design Freedom

The complex geometries, internal channels, snap-fits, and interlocking parts can be easily made without support structures.

3. Scalability

Several components could be made during a build, saving money per unit and allowing for low- to mid-volume production.

4. Reduced Assembly

Functional components can often be 3D printed as a single piece, eliminating the need for fasteners and reducing assembly time.

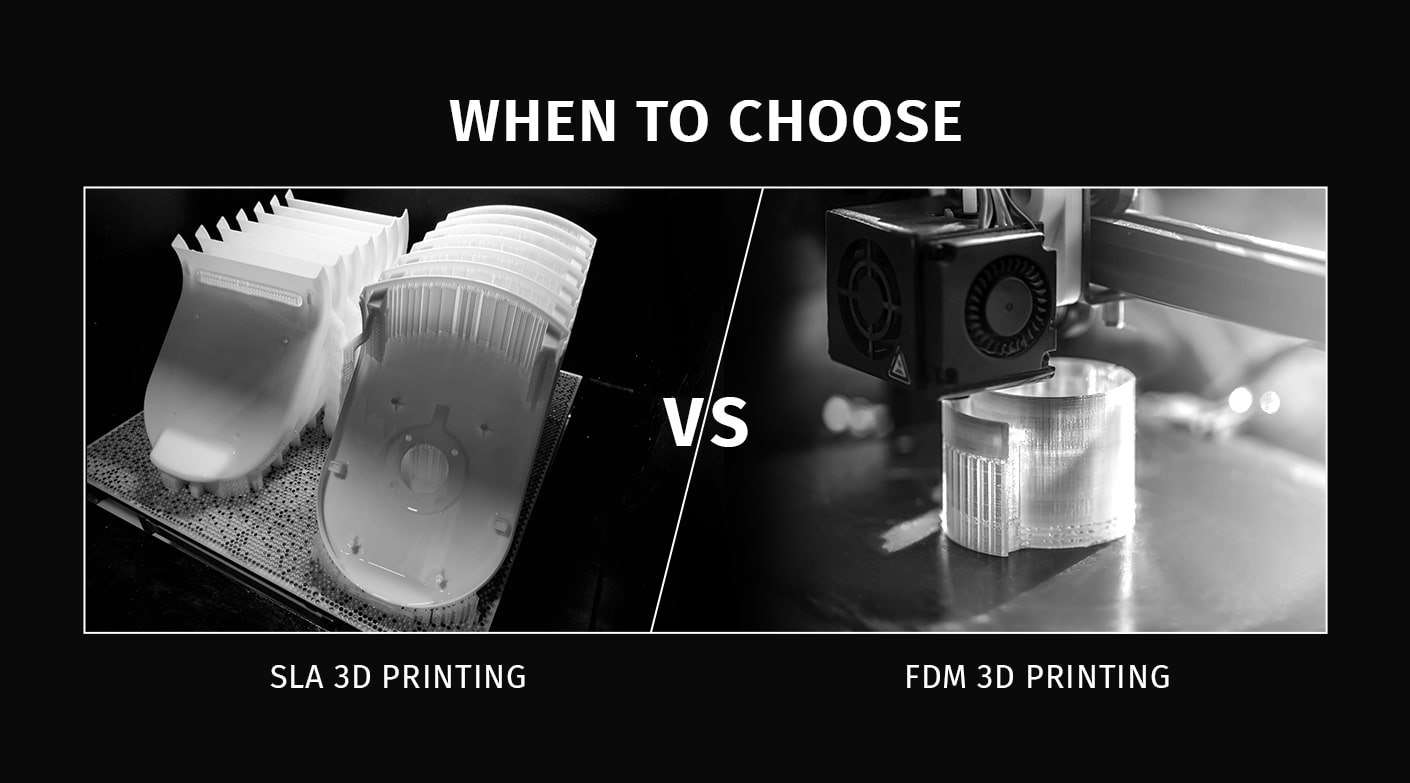

How to Choose Between SLS vs. SLA

Select SLS 3D Printing when your project needs:

- Functional strength

- Complex geometry

- Production-ready performance

- Scalability beyond prototype

Select SLA 3D Printing when your priority is:

- Delicate details and well-polished surfaces

- Visual presentation

- Precision validation

A large number of product teams adopt both technologies, SLA for early design validation and SLS for functional testing and production.

Conclusion

To make smarter manufacturing decisions, it’s essential to understand the differences between SLS (Selective Laser Sintering) and SLA (Stereolithography) 3D printing. While SLA offers exceptional detail and finish, SLS is known for its strength, complexity, and readiness for production. Both technologies play a crucial role at every stage of the product lifecycle.

At Cubein, understanding this difference is fundamental to our approach to creating advanced manufacturing solutions. We help innovators select the right processes, materials, and pathways to turn their ideas into scalable products that customers can trust.

| Let’s make your design a production-ready component with the correct 3D printing technology. |

FAQs

1.What is the primary distinction between SLS and SLA?

SLS works with powdered materials to form high-functionality, strong parts, whereas SLA is employed to cure liquid resin in great detail, creating solid surface models.

2. What are the advantages of SLS 3D printing?

SLS has strength, the capacity to achieve complex geometries, needs no supports, and can be scaled to production.

3. Can SLA 3D printing be used with functional parts?

SLA is optimal with visual and precision models; however, most resin parts are less durable compared to SLS components.

4. What are the comparisons between Selective Laser Sintering and other 3D processes?

Compared to other processes, Selective Laser Sintering 3D printing is more powerful, design-exempt, and more efficient.